Product from Research Projects

Project 1: Spring Roll Seaweed Snack Cutting Machine (PPRN- MOE)

Description of the Project:

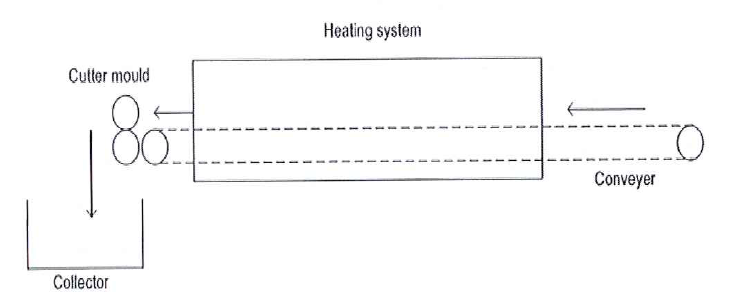

Company has problem with manual cutting of seaweed snack and longer time required for drying. To solve this problem, a continuous drying using blower heating system & counter flow technology will be employed. At the same time, the cutting process will be carried out automatically using cutter mould roller. Figure below show the schematic diagram of the system.

Conceptual Design

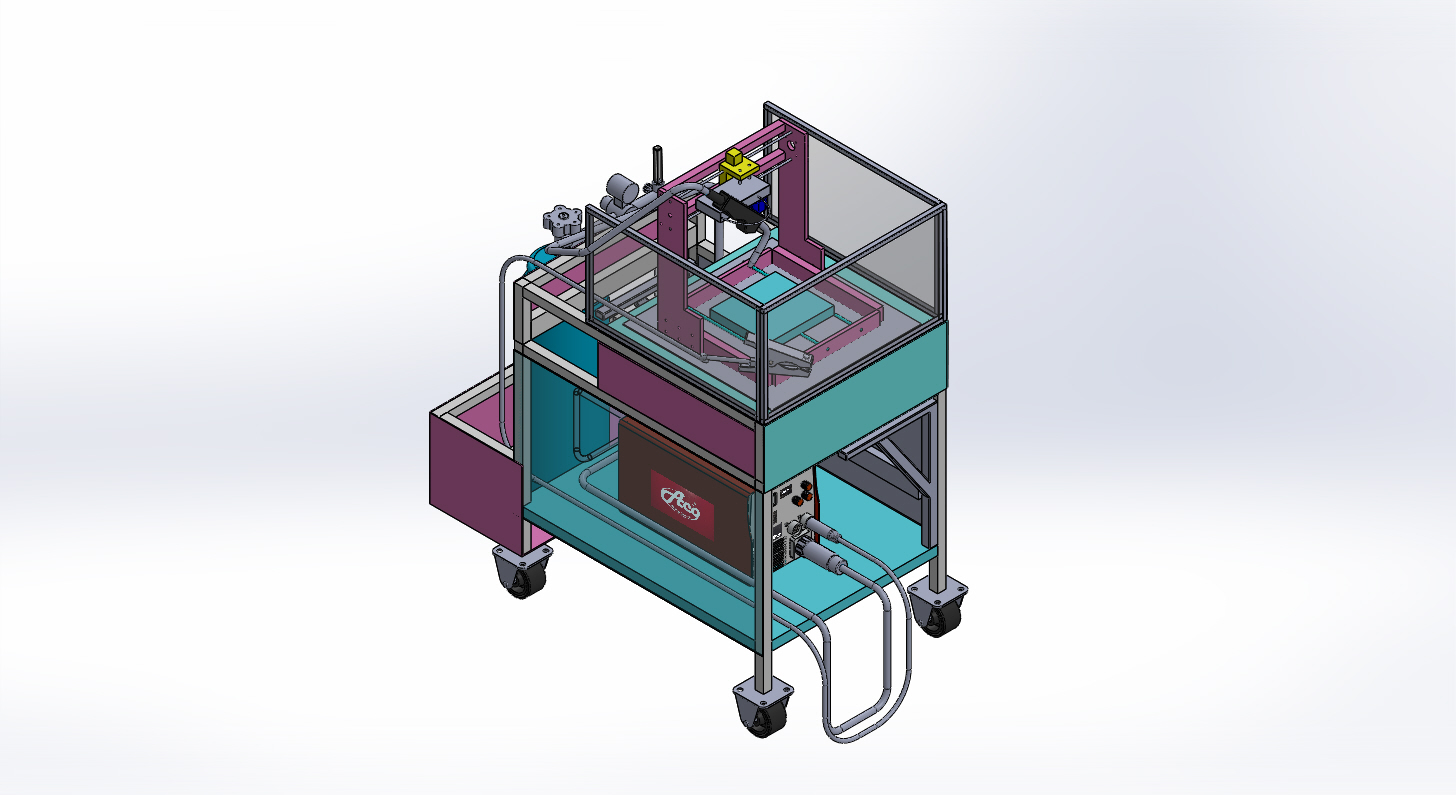

Delivered Machine

Handover ceremony by Deputy Dean (Academic) AP Dr. Abdullah Aziz Saad to Headmaster of the Sekolah Kebangsaan Kuala Kurau, Perak

The machine will be used for teaching and learning activities (Pendidikan Khas Integrasi)

Receipient: Sekolah Kebangsaan Kuala Kurau, Perak.

Status: Completed

Team Members: AP Ir. Dr. Ahmad Baharuddin Abdullah (Leader), Muhammad Azman Miskam, Nor Irwin Basir

Project 2: Isolation Cubical (BJIM- USM)

Description of the Project

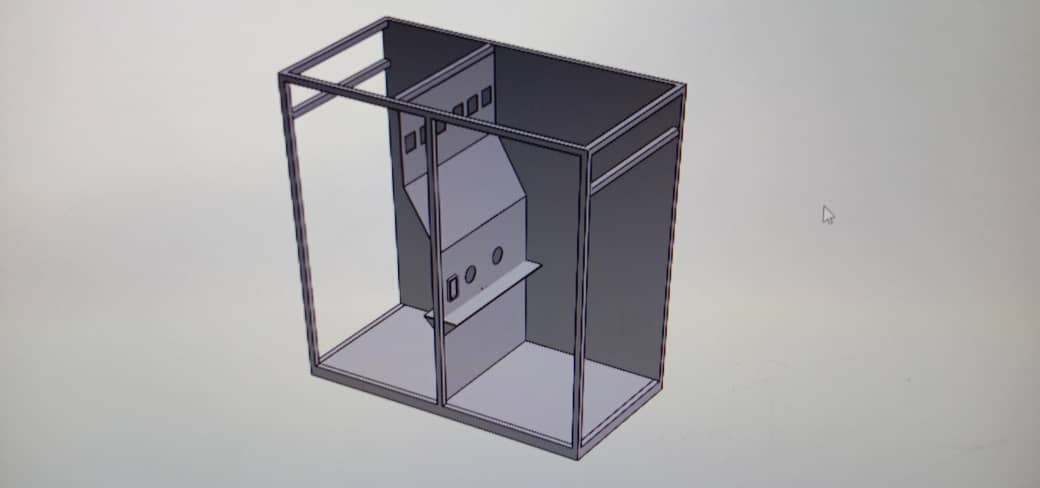

This project was initiated by Jaringan Industri and Masyarakat (BJIM) USM and purposely prepared for Pusat Sejahtera USM usage in order to avoid or to minimize risk of health personal from infected during covid-19 sampling or swap test on student and staff with symptoms. The cubical was fully developed by staff from the School of Mechanical Engineering USM, lead by Assoc. Prof. Ir. Dr. Ahmad Baharuddin Abdullah.

Conceptual design of the cubical

3D model of the cubical

Delivered cubical

Receipient: Pusat Sejahtera, USM

Status: Completed

Team Members: AP Ir. Dr. Ahmad Baharuddin Abdullah (Leader), Dr. Normala Abdul Wahid, Dr. Sharizal, Wan Mohd Amri and Muhammad Azman Miskam.

Project 3: 3D welding machine

Description of the product

Metal additive manufacturing is a relatively new technology brought to enhance the available 3D printing technology which is polymer based in terms of product functionality. However, the technology is very expensive. In this project, a relatively cheap and user friendly metal based 3d welding machine developed based on DIY concept using modular approach was developed. To date, it already benefited many students in their projects. The machine consist of 4 independant module, a) welding set, (b) CNC router, (c) main body and (d) XYZ table.

CAD model of the machine

The machine utilized the typical MIG machine setup as shown in figure below. It is attached to the CNC router that allow for XYZ movement. It is programm

Welding torch setup

Status: Ready for commercialization

Team Members: Zarirah Karrim Wani (Leader), Assoc. Prof. Ir. Dr. Ahmad Baharuddin bin Abdullah.

Project 4: Wood breaker and saw dust machine

Description

Gaharu or agar wood tree is a special tree used for its distinctive fragrance in incense, perfumes, and traditional medicine. Support technology and machinaries are required in processing the wood before the oil can be extracted. Utilizing in-house facilities and expertise, we have produced two machines, i.e. wood breaker and saw dust machine (not explained here).

Figure 1: Wood breaker

The wood breaker is equipped with 2 blades that can be easily replaced or when it's requires resharpen. Safety fance is use to cover the blade for safety of the operator once it rotating and for mobility, heavy duty wheels were utilised.

Status: Ready

Team: Muhammad Amirun (Intern) and Assoc. Prof. Ir. Dr. Ahmad Baharuddin Abdullah