Metal Additive Manufacturing and Circular Economy

Nowadays everybody talk about sustainable manufacturing and extending lifecycle of a component or part, in this case metal. There are a lot of research is running and writing made about the initiatives. For example about the opportunities and barriers, which recently published at https://insidemetaladditivemanufacturing.com/2024/05/01/building-a-circular-economy-with-metal-am-opportunities-and-barriers/. Various terms and names are referring thru these inititiaves such as part remanufacturing, restoration, refurbishment and repair. The main objective is to extend the product/part life cycle and enhance the viability of in manufacturing process.

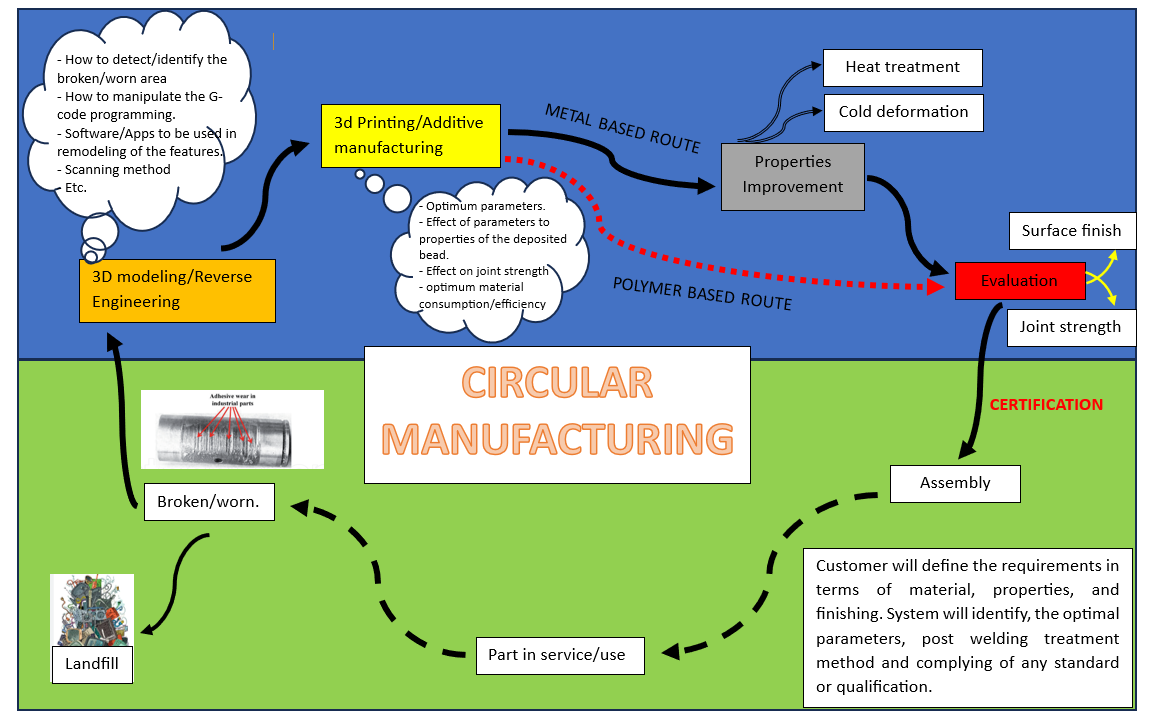

We are at Metal Forming Research Lab (MFRL) also take the initiatives and utilizing the wire arc additive manufacturing technique. The exploration is divided into 5 modular stages; begins with broken/damage part that may gone thru 1) 3d modeling via 3d reconstruction facilties like 3d scanner and 3d modeling software, 2) 3d printing system, where optimial process parameters were identified and implemented. 3) Properties enhanncement via heat treatment or thermo-mechanical approach, 4) Evaluation in terms of strength and surface quality and finally 5) Compliance to the standard or industry sepecification before the part/component can be reinstalled and back to service as shown in the Figure 1.

Figure 1: The concept of circular manufacturing via additive manufacturing innitiative.

Numbers of fundamental studies were carried out to discover the potential of the technique and improvement can be made. Until now there numbers of publication made;

a) Tribological performance;

1. https://journals.sagepub.com/doi/abs/10.1177/13506501241254885

2. https://semarakilmu.com.my/journals/index.php/appl_mech/article/view/3920

b) Tensile strength and impact toughness

1. https://journals.sagepub.com/doi/abs/10.1177/09544089231215203

3. https://link.springer.com/chapter/10.1007/978-3-030-89992-9_12

However, there are fundamentals issues to be resolved, mainly the economic perspective, whether the repair work is worth to be carried out. In the future, we are focusing in this area, targeting to define the criteria of high-value component form various aspects.