Tooling Design - Material Utilization

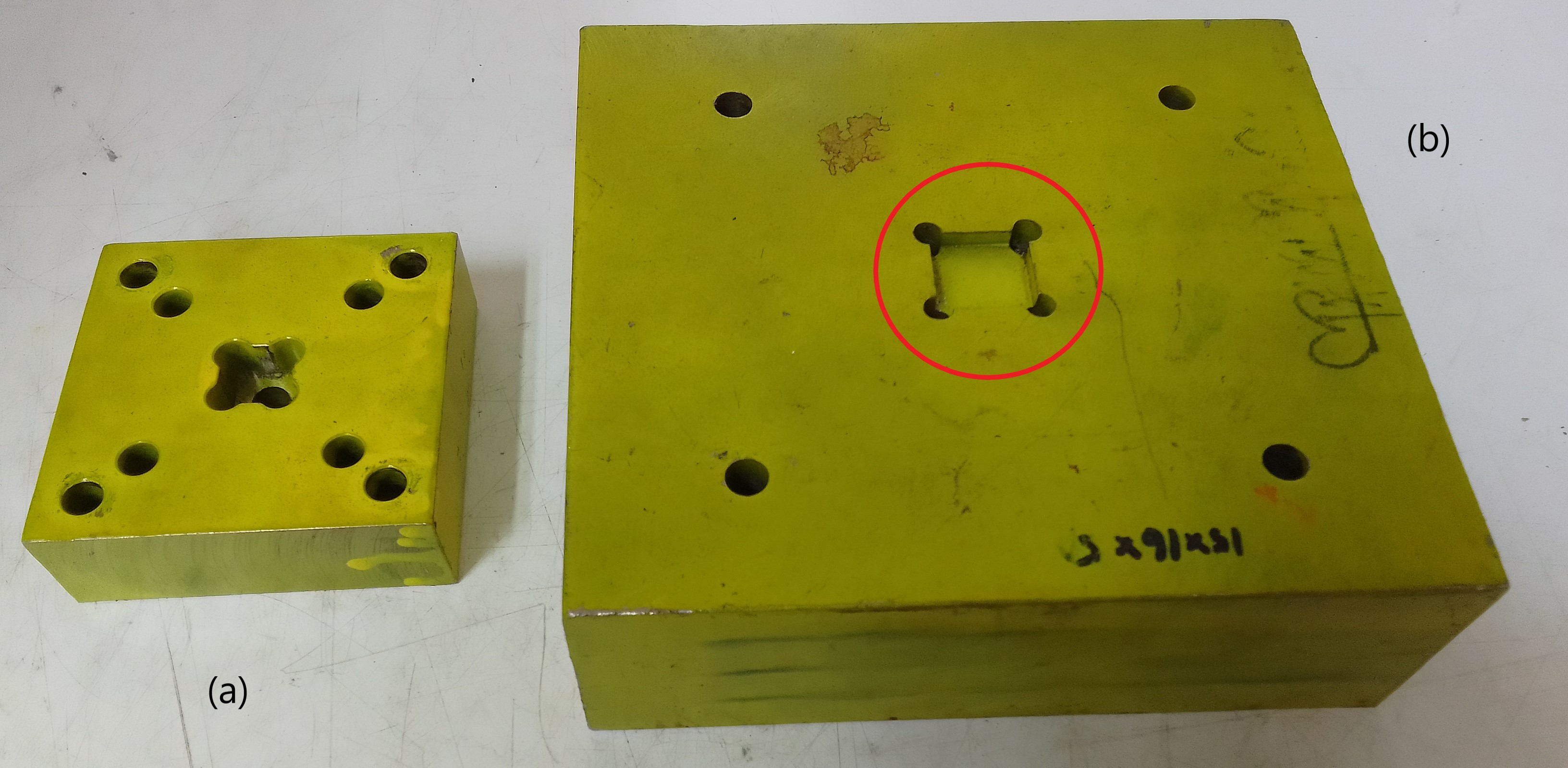

Material utilisation is one of the important criteria in tooling design. It can be described as the optimal usage of material in the fabrication of tooling parts. Furthermore, it may shorten the machining time and reduce waste. Figure 1 illustrates an example of material utilization. The material needed for the part in Figure 1(a) is relatively less than the part in Figure 1(b). For about the same function, part (b) has less utilisation compared to part (a).

Figure 1: Example of material utilization

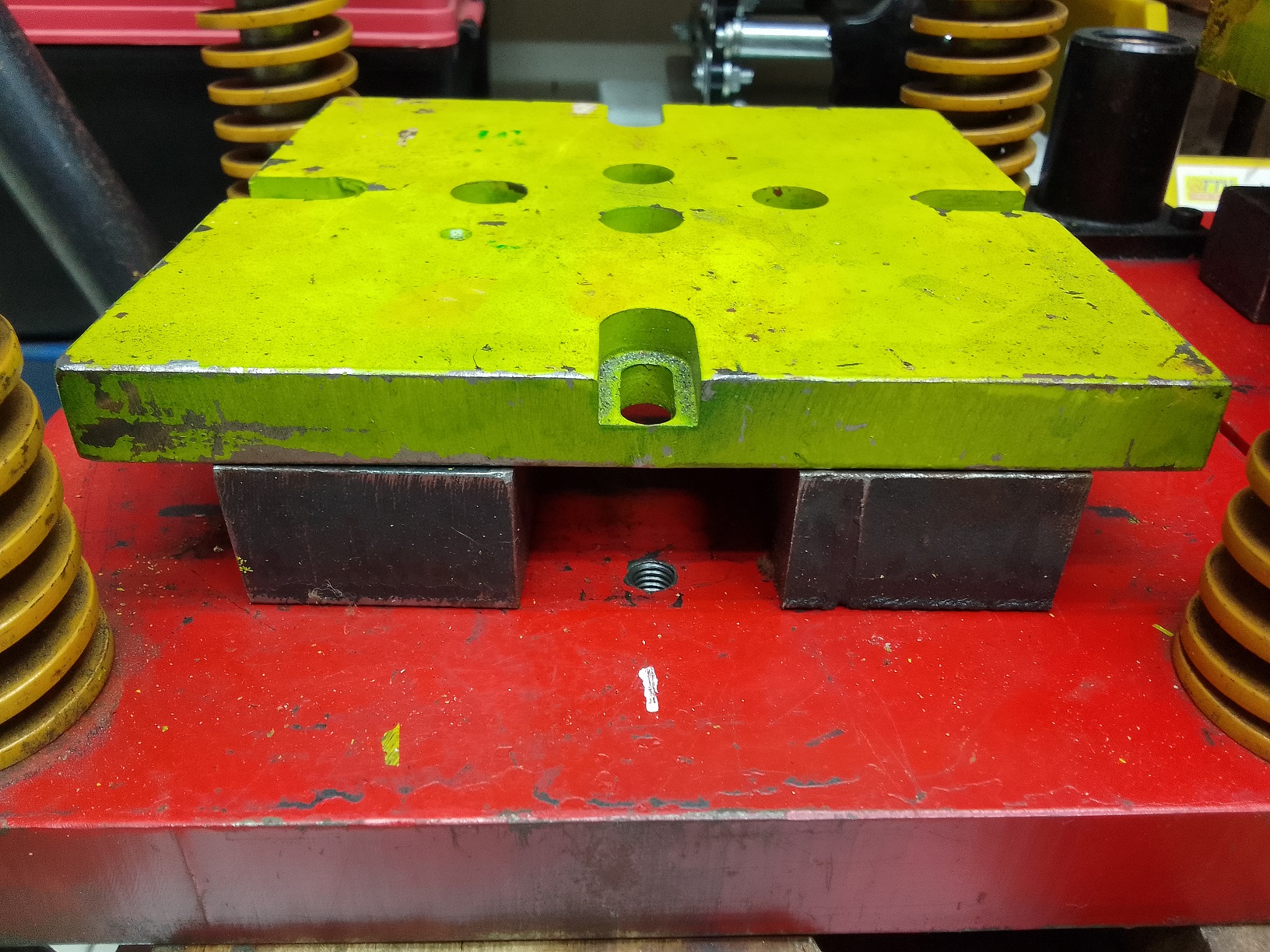

One of the reasons to use thicker material is to achieve the adequate height needed for the set amount of stroke by the puncher or die. However, there are many methods to tackle this issue. One of them is by using a simple block, as shown in Figure 2. This approach offers various advantages, including providing space for scrap to drop underneath. The block is relatively simple and requires less time to prepare. The same approach can be applied to the puncher plate.

Figure 2: Use of block to raised the die/puncher plate

Note: Images were obtained from the project made by student for their tooling design project.