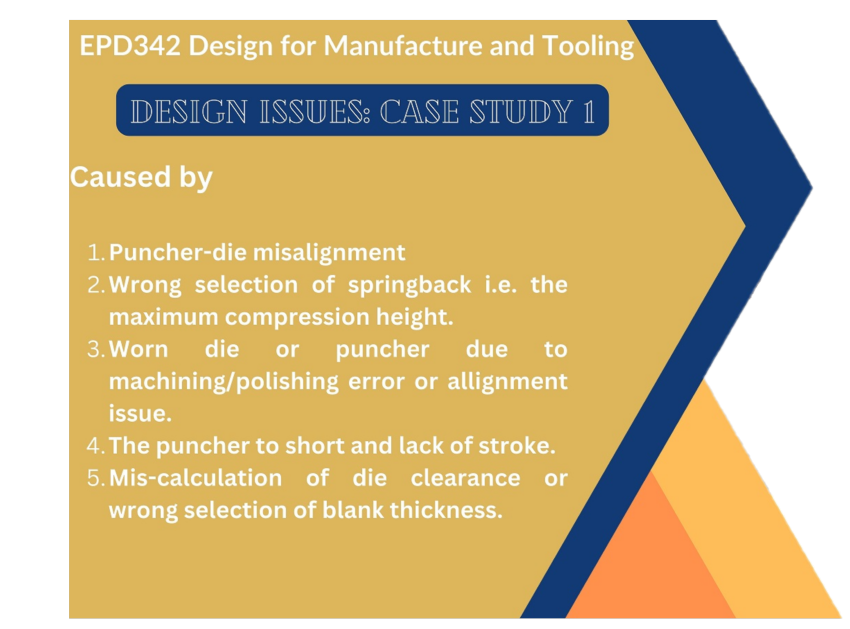

Tooling Evaluation - Case Study 1

During trial, we can know either the tooling working as intended or not. Good design and nice 3D modeling not necessarily free any issued during the fabrication. Precise and good tooling machining and assembly still cannot confirm the tooling will work correctly during the trial. Therefore, progressive improvement thru out the process is crucial. In this article, we will discuss one of the problem that may occur during the trial, i.e. the product not well cut even though puncher-die mark can be seen. There may cause of the raised issue. Below are figures illustrated the said issue.

There are many solution, however before that, causes of the defect need to be understood first.

In the next article, the solution will be described together with the proven changes made on the tooling.