Tooling Design – Overdesign Vs underdesign

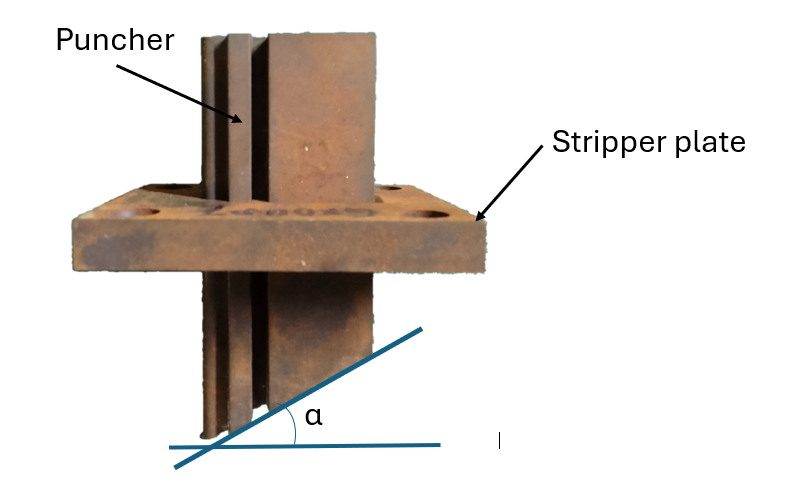

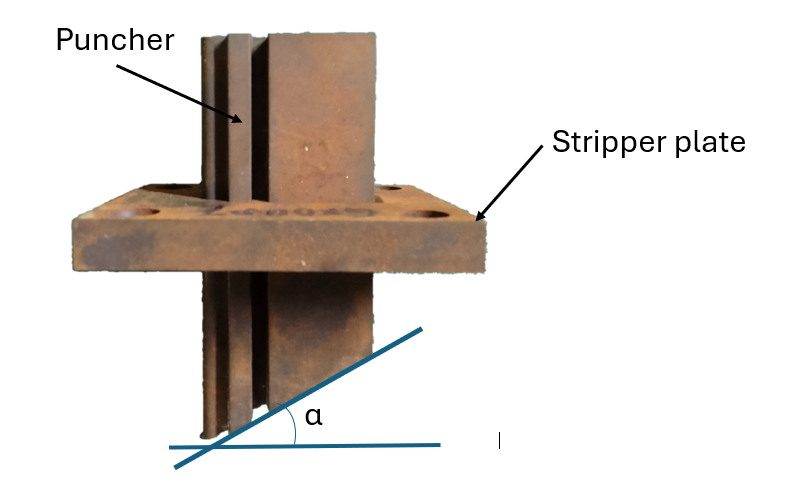

In the design of a product or part, over- or underdesign needs to be avoided or at least minimized. Overdesign means designing something too much, excessively complex, or exceeding the usual needs. In contrast, underdesign is about design inadequately. Same to tooling design; underdesign can be due to material saving or lack of resources; as a result, rejection on the manufactured part may be high, or the tooling may not last long. For the case of overdesign, material waste may be higher, time to machining increases (https://artizono.com/punching-force/), and productivity may be low. As in the case of the bevel puncher as in Figure 1, which was produced with a larger bevel angle, approximately 42 degrees. Studied by Cavusoglu et al. (2022) found that increasing angle can reduce noise and blanking force. They studied until 16 degrees only. Even puncher with bevelled was less wear compared to others (Shih et al., 2017).

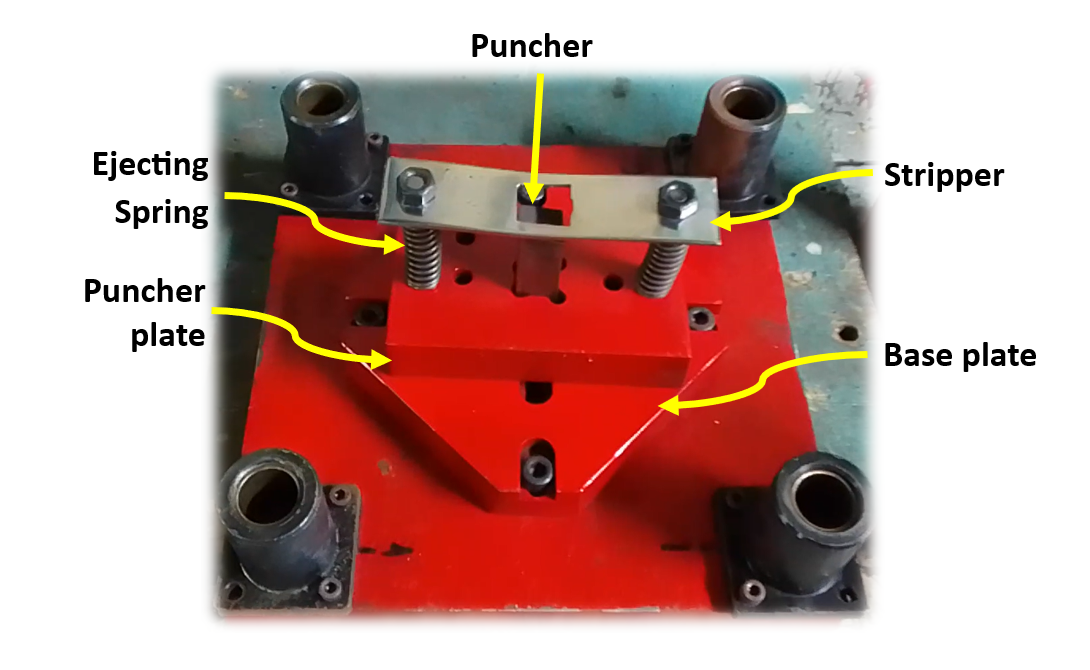

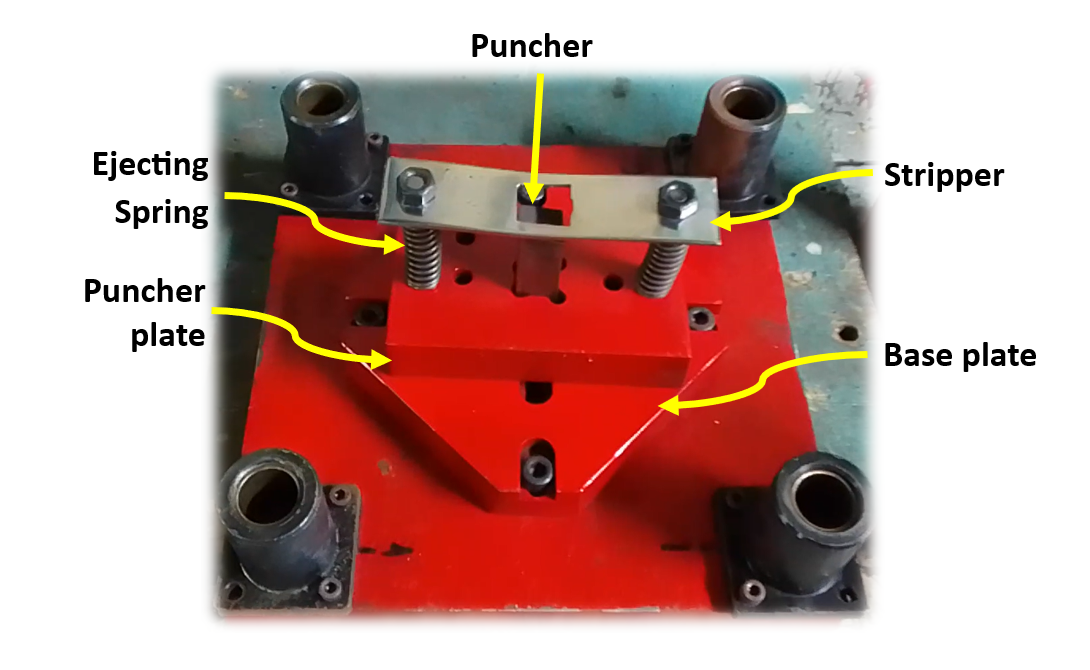

Hence, what is the optimal angle? Khleif and Jasim (2018) suggest 10 degrees for optimal cutting quality and force needed. For the underdesign case, what is the appropriate thickness for a stripper plate by referring to Figure 2? The answer will be in the next writing.

Figure 1: Bevelled angle too large.

Figure 2: The stripper plate is too thin causes its bent during the blanking

References

Cavusoglu, Onur & Gürün, Hakan & Kafkas, Firat & Efendioglu, Saziye & Mert, Faruk. (2022). The effects of punch angle in noise and force formation for sheet metal blanking process. Proceedings of the Institution of Mechanical Engineers Part E Journal of Process Mechanical Engineering. vols. 236. 1477-1484.

Punching Force in Metal Fabrication: A Comprehensive Guide. (2024). https://artizono.com/punching-force/. Access on 29 August 2024.

Shih, Hua-Chu & Zhou, Dajun & Konopinski, Bruce. (2017). Effects of Punch Configuration on the AHSS Edge Stretchability. SAE International Journal of Engines. 10. 10.4271/2017-01-1705.

Ali Abbar Khleif and Ahmad Saad Jasim (2018). The Effect Of Blanking Shear Angle On The Shearing Forces Of Blanked Carbon Steel Sheets, International Journal of Mechanical Engineering and Technology, 9(11), 1120–1128.