Eid Mubarak 2025

We would like to wish Eid Mubarak (Selamat Hari Raya Aidil Fitri) to all alumni, collaborators and supporters.

We would like to wish Eid Mubarak (Selamat Hari Raya Aidil Fitri) to all alumni, collaborators and supporters.

We are pleased to welcome two newly joined researchers to the MFRL, Dr. Anwar and Mr. Mohzani. Hopefully their expertise and knowledge can assist to bring the lab further. Both are well-experienced lecturers at the School of Mechanical Engineering, USM. Recently Mr. Mohzani involved in supervising a few FYP students on wire arc additive manufacturing related projects. Similarly, Dr. Anwar, who are expert in friction stir processing of dissimilar materials and material characterization.

Congratulation to Kamarul Al-Hafiz for this achievement. Hope it will motivate you and others to work harder. Keep it up guys. Thank you.

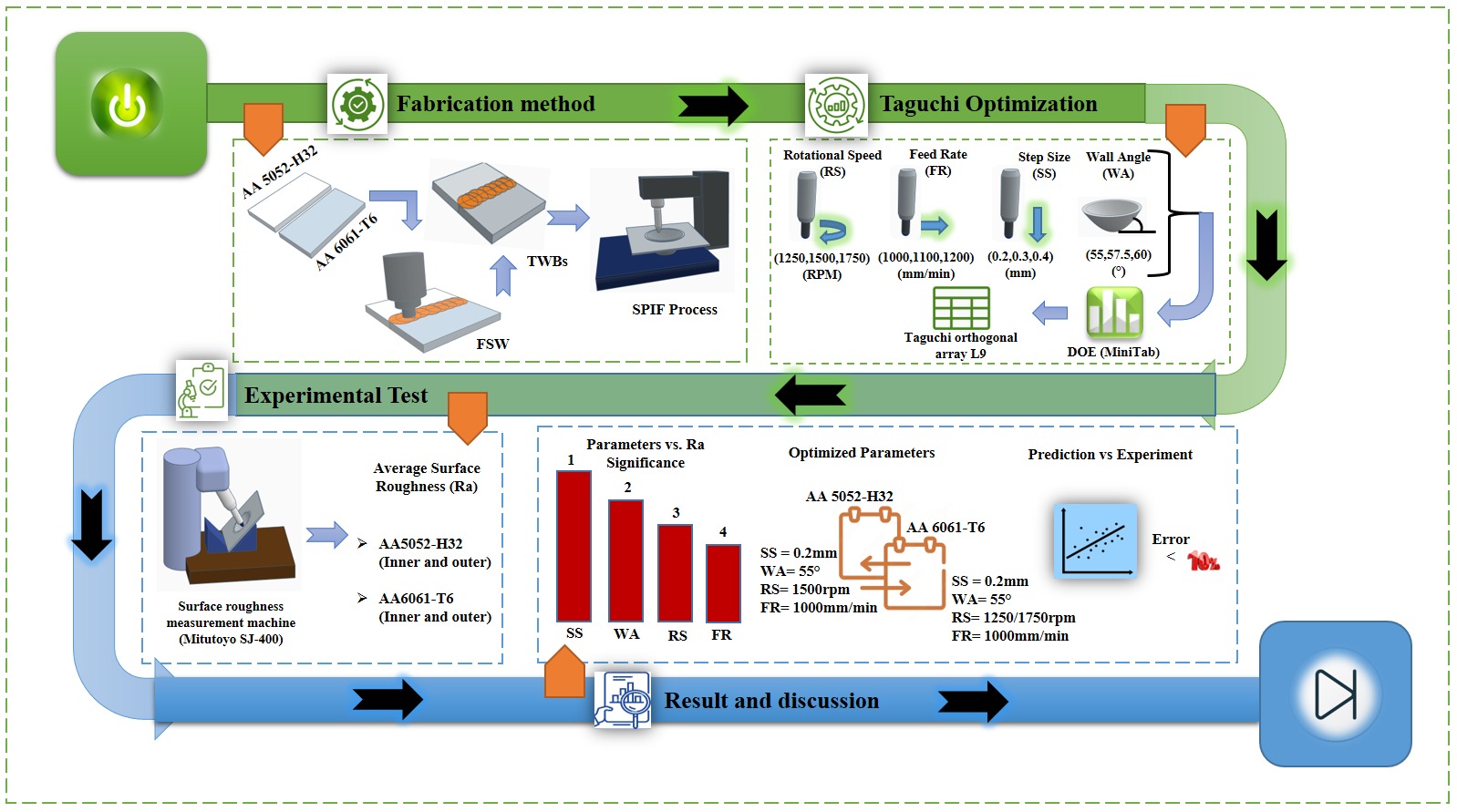

Kamarul Al-Hafiz Abdul Razak, Ahmad Baharuddin Abdullah & Norzalilah Mohamad Nor. (2025). Effect of Single Point Incremental Forming (SPIF) Process Parameters on Surface Roughness of Dissimilar Tailor Welded Blanks using the Taguchi Method, Jurnal Kejuruteraan 37(1), pp. 299-308

Full paper can be accessed from this link https://doi.org/10.17576/jkukm-2025-37(1)-20

Three of our members presented at an international conference hosted by Egypt's Helwan University. The conference is being held virtually. Our goal is to increase our visibility in the research community by taking part on an international level. Additionally to establish networking to foster collaboration.