Tooling Design – Overdesign Vs underdesign

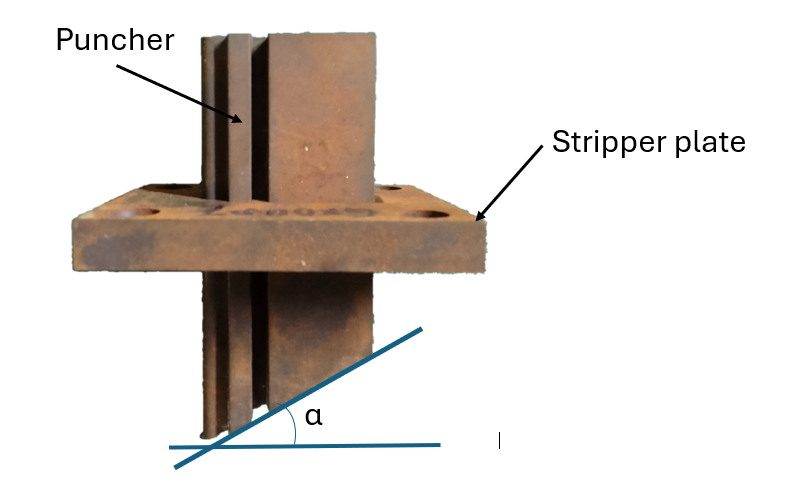

In the design of a product or part, over- or underdesign needs to be avoided or at least minimized. Overdesign means designing something too much, excessively complex, or exceeding the usual needs. In contrast, underdesign is about design inadequately. Same to tooling design; underdesign can be due to material saving or lack of resources; as a result, rejection on the manufactured part may be high, or the tooling may not last long. For the case of overdesign, material waste may be higher, time to machining increases (https://artizono.com/punching-force/), and productivity may be low. As in the case of the bevel puncher as in Figure 1, which was produced with a larger bevel angle, approximately 42 degrees. Studied by Cavusoglu et al. (2022) found that increasing angle can reduce noise and blanking force. They studied until 16 degrees only. Even puncher with bevelled was less wear compared to others (Shih et al., 2017).

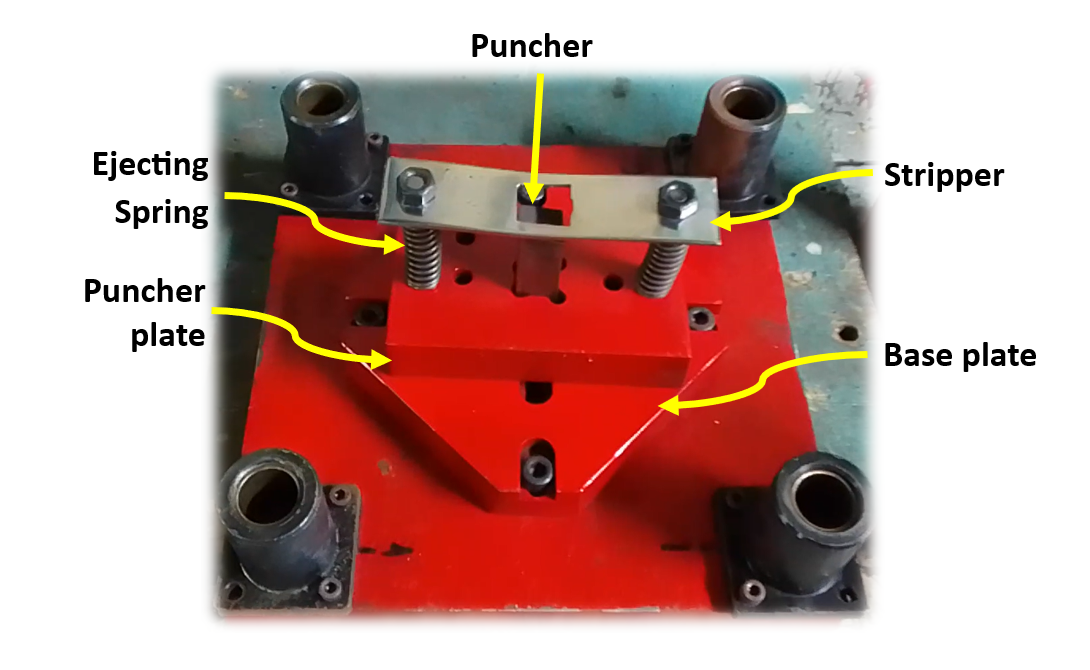

Hence, what is the optimal angle? Khleif and Jasim (2018) suggest 10 degrees for optimal cutting quality and force needed. For the underdesign case, what is the appropriate thickness for a stripper plate by referring to Figure 2? The answer will be in the next writing.

Figure 1: Bevelled angle too large.

Figure 2: The stripper plate is too thin causes its bent during the blanking

References

Cavusoglu, Onur & Gürün, Hakan & Kafkas, Firat & Efendioglu, Saziye & Mert, Faruk. (2022). The effects of punch angle in noise and force formation for sheet metal blanking process. Proceedings of the Institution of Mechanical Engineers Part E Journal of Process Mechanical Engineering. vols. 236. 1477-1484.

Punching Force in Metal Fabrication: A Comprehensive Guide. (2024). https://artizono.com/punching-force/. Access on 29 August 2024.

Shih, Hua-Chu & Zhou, Dajun & Konopinski, Bruce. (2017). Effects of Punch Configuration on the AHSS Edge Stretchability. SAE International Journal of Engines. 10. 10.4271/2017-01-1705.

Ali Abbar Khleif and Ahmad Saad Jasim (2018). The Effect Of Blanking Shear Angle On The Shearing Forces Of Blanked Carbon Steel Sheets, International Journal of Mechanical Engineering and Technology, 9(11), 1120–1128.

Add a comment4 Days at FLAME 2024 - Part 2

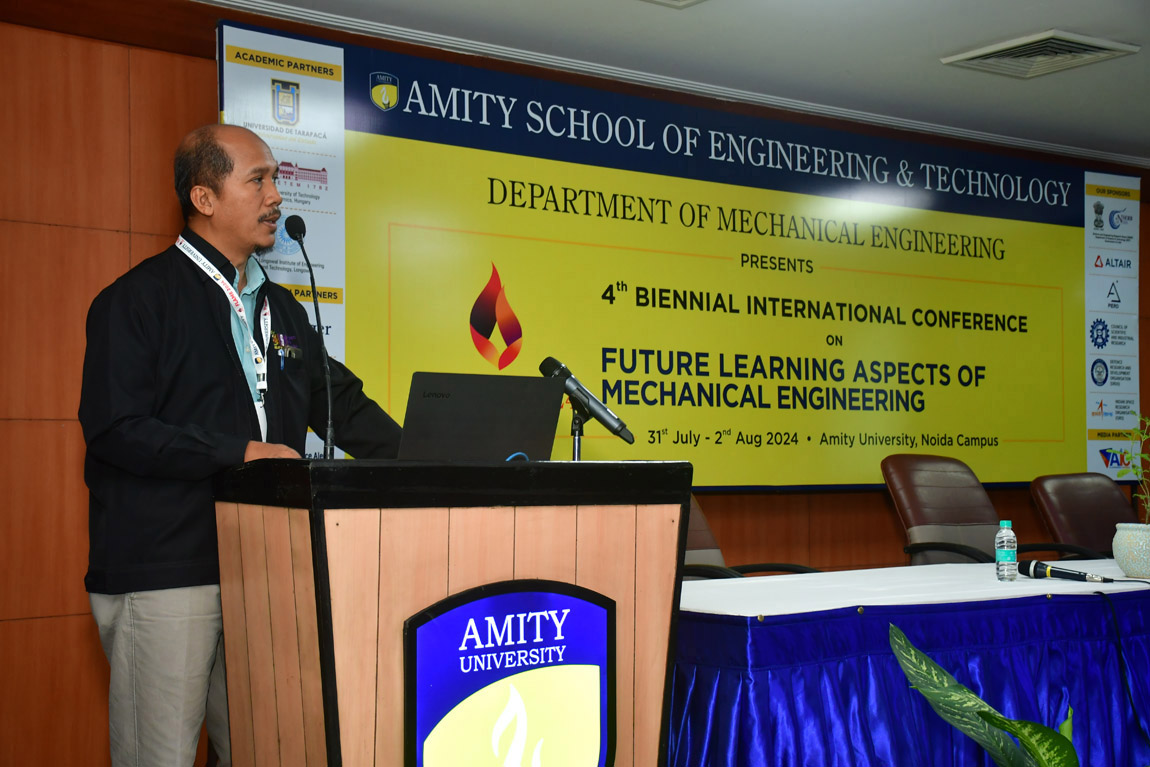

It is an honour to be part of the conference and, together with researchers from various countries, share knowledge. At the conference, I was shared our latest research in the FSW and our findings. This is one of the research foci at the MFRL, and we are welcoming collaborators from any part of the world to be our research partners.

From my observation, researchers from India are very strong in FEM and other simulation tools. Most of the presenters shared their research on the application or development of FE tools in various applications.

4 Days at FLAME 2024 - Part 1

First experience to go oversea and present in a conference as a keynote speaker is a new milestone to me as an academia. Interetingly, this is also the first time in India. Thank you to the organzier of FLAME 2024 to invite me to the conference. AMITY University is one of the private university in Noida, Uttar Pradesh. The university is very calm and beautiful. I have seen many non-Indian students. The conference is organized by the Department of Mechanical Engineering, headed By Prof Basant and interestingly there are many volunteers from undergraduate student to ensure smooth programms. Even two students wait for me at the airport.

I have been placed at the guest house during my stay. Overall is good and all basic needs are provided. Facilities within the university actually gives advantages to the visitor like me and easy for organizer in terms of logistic and arrangement. I will share other experience in the next writing.

Add a commentWelcome 2 Internship Students

Metal Forming Research Lab would like to welcome 2 students who are doing their internship. Muhammad Amirun and Faris Hazmie. Amirun from POLIMAS will be here for 20 weeks to complete his practical for his Diploma in Mechanical Engineering (Manufacturing), while Faris from IIUM, will have a 10 weeks practical as part of his Degree in Engineering (Manufacturing). Hopefully they will gain as much knowledge, exposure and experience during the internship.

Both of the them will gone through a separate schedule, since they are from different level of study.

Muhammad Amirun

Faris Hazmie

Add a comment